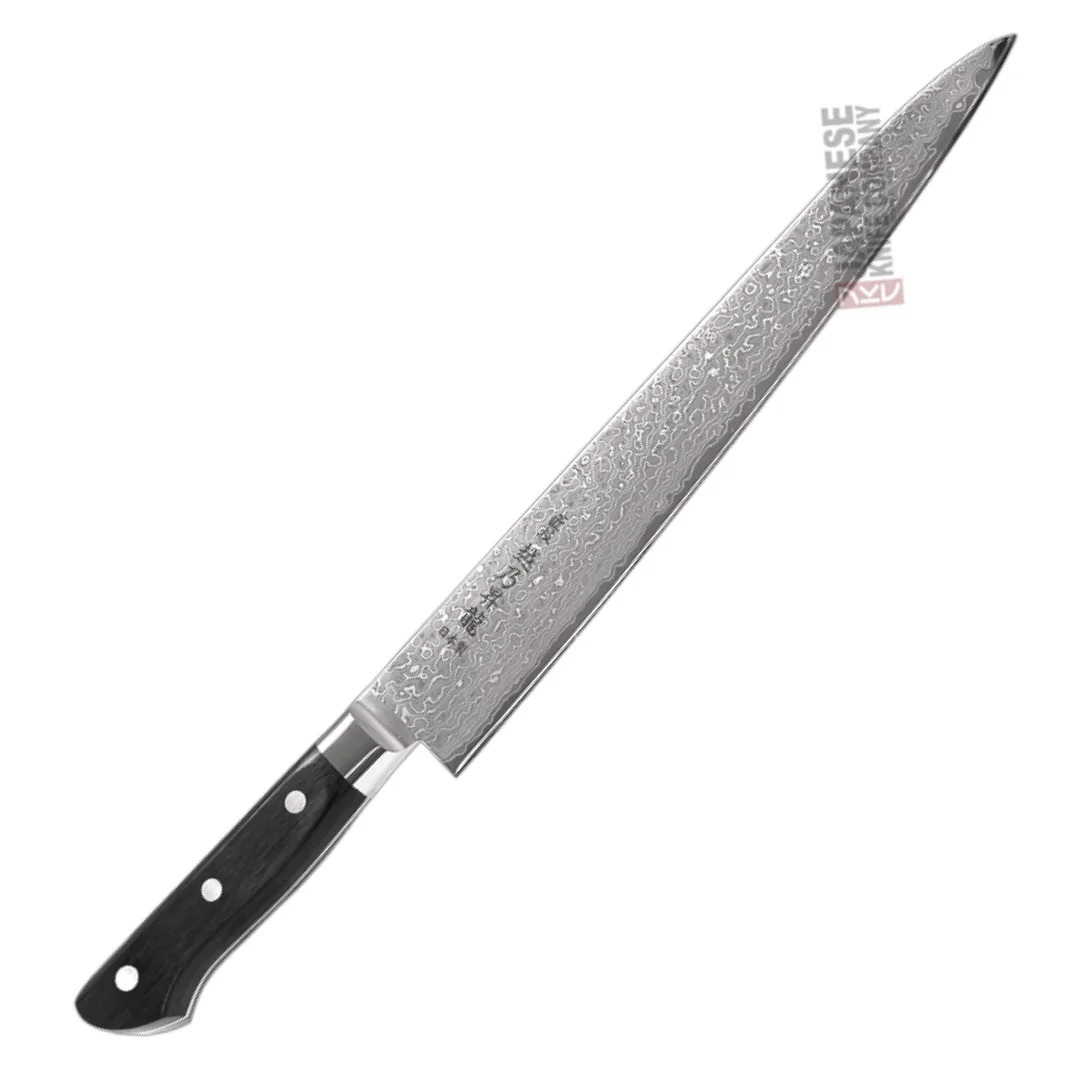

The JKC 63 Layer Damascus Collection is forged by sandwiching a sheet of High Carbon Chrome Vanadium (HCCV) stainless steel between 31 Layers of Nickel stainless on either side. The HCCV central core has .8% – .95% Carbon and the ability to hold a considerably more enduring edge (usually 40% – 60% longer) than the finest Western knives. The multiple layers are twisted drilled and compressed several times during the layering process; once ground and treated with Aqua Regia (a mild acid solution), intricate wood like patterns appear that mesmerise the eye.

The final tempering to 58:60 HRC a blade capable of being honed to an edge so sharp it would be at home in any surgeons hand. The soft 31 layers on either side protect the fine central core. The inherent quality of the HCCV steel to produce small carbides combined with the softness of the outer layers makes this one of the easiest knives to re sharpen. Furthermore, the small carbides produce an ultra silky smooth edge rendering textures virtually imperceptible.

GYUTO (Gyu – cow & To – sword):

This is the Japanese interpretation of a Western Chef’s knife. It is flat from the handle end for about 1/3rd of the edge and then curves to the tip. It is ideal for the Western style of roll cutting.

Function – Multipurpose chef knife. For Slicing, Dicing, Mincing, Filleting and Chopping of meat, fish and vegetables.

Normal length – 180mm to 300mm.

Tip: With the edge flat for about 1/3rd of the blade – 210 mm or longer the knife-edge profile is the same as a 180mm Santoku from the handle to tip and the same as a 180mm Gyuto from the tip to handle – so essentially a 180mm Gyuto & 180mm Santoku in one knife. The 210mm is the most favoured size for most chefs.

Reviews

There are no reviews yet.