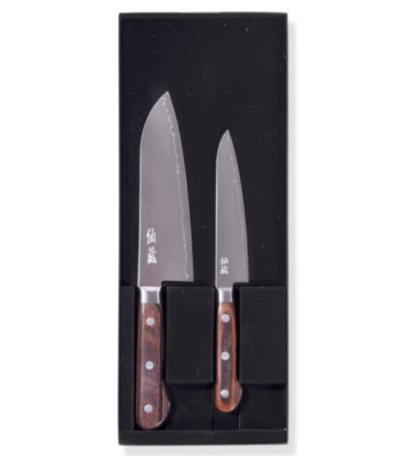

JKC AUS10

Over the past 10 years or so, VG10 (a High Carbon Super steel) has been used in the manufacturing of high-end knives by the best makers. Whilst this is a fantastic material when forged to create a high-density blade to add toughness, it can be harder to re-sharpen than normal Japanese forging that’s made with a ‘soft’ hand.

As many of our chefs work in environments where their knives are heavily used and often abused! We wanted to ensure a knife that is capable of withstanding tough conditions whilst still capable of razor-edge sharpness that is easy to maintain.

In conjunction with the workshop in Seki that makes our Yasuo Collection we decided to cold forge a 3 layer steel with an AUS 10 core rather than the VG10 of the Yasuo Series. AUS 10 is easier to sharpen than VG10 and to increase the toughness of we use 3 layers rather than 33 Layer steel, so the core is thicker, this in combination with the cold forging ensures the crystalline structure is denser.

Chefs are reporting that at under £100 for a Santoku this is an amazing knife and sure to delight the most fastidious user.

JKC AUS10 Gyuto (3 Sizes)

- 180mm / 210mm / 240mm Gyuto

- Matte finish

- AUS 10 Stainless Steel

- 3 Layers

- 60±1 HRC

- Double Bevelled and Full Tang

- Handle: Brown Pakkawood with Stainless steel bolster

- Location: Seki, Japan

Select options

This product has multiple variants. The options may be chosen on the product page

JKC AUS10 Santoku 165mm

JKC AUS10 Utility (2 Sizes)

- 135mm / 150mm Utility

- Matte finish

- AUS 10 Stainless Steel

- 3 Layers

- 60±1 HRC

- Double Bevelled and Full Tang

- Handle: Brown Pakkawood with Stainless steel bolster

- Location: Seki, Japan

Select options

This product has multiple variants. The options may be chosen on the product page